Leeds History

The history of Leeds and specially selected photographs

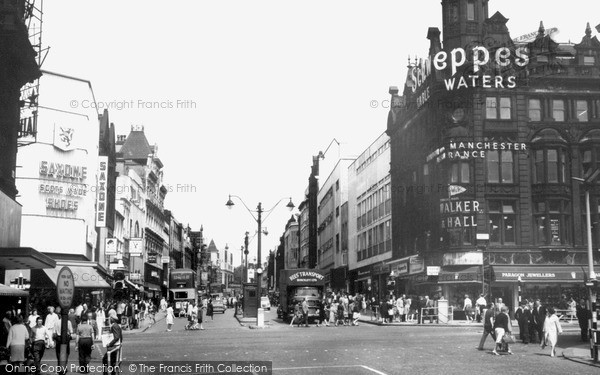

Leeds was the industrial powerhouse of the West Riding, and like all our great industrial cities, it grew from much humber beginnings.

When the Domesday Book was being compiled in 1086, Leeds was little more than an agricultural village huddled between the river and what is now Kirkgate. There were 35 families, a priest, a church and a mill - the latter doing well enough to be worth four shillings a year. The village was under the lordship of Ilbert de Lacy, William the Conqueror's deputy in those parts, and as such seems to have escaped the wrath of the Conqueror when he laid waste to much of Yorkshire following an uprising in 1070. Around 1100 de Lacy sublet Leeds to Ralph Paganel, who was also the tenant-in-chief of Headingley and othe lands throughout the county. Paganel, rich and powerful in his own right, was appointed High Sheriff of Yorkshire in 1110.

In Leeds and the surrounding villages, cloth manufacture seems to have been underway of a small scale by the 12th century, almost certainly influenced by the close proximity of the Cistercian abbey of Kirkstall. Endowed by Henry de Lacy in thanks to the Blessed Virgin, Kirkstall, like the Cistercian abbeys of Fountains, Rievaulx and Jervaulx, kept huge flocks of sheep for wool. In the 12th century most of the wool was sold for weaving in Flanders and Northern Italy, though there was a considerable amount of weaving done at both York and later Beverley, with Leeds, Wakefield, Whitby and Selby the poor relations. By the late 14th century, however, times were changing. The guilds at York and Beverley was so over-regulated and over-taxed with guild levies that they were unable to rise to the challenge of cheaper textiles from the likes of Leeds, Halifax and Wakefield, where production costs were lower. Even so, as late as 1470 Leeds was still being described as 'near Rothwell'. Yet within the next 50 years the town would emerge as the leading centre in Yorkshire for the trade in woollen cloths, and by 1560 was probably similar in size to Bradford. There were houses on both sides of Briggate as far as the Headrow, and others beyond Timble Bridge over Sheepscar Beck. The population at this time would have been around 3,000, if the outlying hamlets of Woodhouse, Buslingthorpe, Potternewton and Knowsthorpe are taken into consideration.

By 1612 the population had probably doubled, due in part to people coming to the town in search of work. Building development now extended along Kirkgate, Boar Lane, Vicar Lane and Swinegate. An ever-growing mixture of housing and workshops sprung up, as the position of Leeds within the textile industry continued to strengthen. The town was no longer simply engaged in manufacturing: it had become the leading finishing centre in the West Riding for cropping, dyeing and dressing. Leeds merchants traded aggressively both at home and abroad, securing markets previously dominated by the merchants of York, Beverley and Hull.

By 1600 Leeds had established itself as the most important of all the cloth fairs in the country. Every Tuesday and Saturday tables were set up on the bridge over the Aire at the bottom of Briggate. When the market bell tolled the sellers would move to the tables, which they had to share, and stand in line behind their pieces. The traders entered when the bell stopped tolling. Business was done in a whisper so that other buyers and sellers could not hear the price agreed. After a couple of hours the bell tolled to signal the end of the market and everything was cleared away. Daniel Defoe reckoned that in a morning somewhere between £10,000-£20,000 worth of cloth was traded.

By 1710 these open-air markets were being challenged by Cloth Halls, where business could be done whatever the weather outside. Leeds answered the challenge in 1711 with the opening of a hall for White Cloths. In 1755 a new and much larger purpose-built White Cloth Hall was opened, followed a few months later by a Mixed Cloth Hall.

By 1775 the population of Leeds is thought to have been about 17,000 and by the time of the first census of 1801 it had rocketed to 53,000. The coming of the factory system led to thousands leaving the countryside in search of work. The work they found was alien to them: strict discipline, regular attendance, long hours and unsafe working practices. Yorkshire mill owners were at the forefront when it came to employing child labour in almost slave-like conditions. Many of these children were sent north from London workhouses. Those who ended up in the mills around Leeds were luckier than the children sent to Bradford. In Leeds they worked a 12-hour day; in Bradford, 13. In both places children were beaten to keep them awake.

With the factory system came machinery. As with every subsequent generation, the factory workers of the early 19th century equated mechanisation with a threat to jobs. In the 1800s reaction to the threat manifested itself in the movement that came to be known as Luddism. The earliest cases in Yorkshire date from 1811 to 1812 when croppers rebelled against the introduction of shearing frames.

It was the combination of the factory system and the application of steam power that led to the concentration of textile production in a handful of towns, including Bradford, Huddersfield, Dewsbury, Batley, Bingley and Leeds. By the mid 19th century there was an enormous diversity in the manufacturing base of the town. Though woollens still dominated the scene, the flax industry employed over 9,000 workers and other industries included rope, glass, earthenware and paper manufacturing.

Coalmining was another major industry in the area. At its height there were 102 collieries employing 5,000 miners, with an annual output of 2.5 million tons. Engineering also played an important part in the development of Leeds. Fairbairn and Lawson manufactured flax and tow machinery, much of which went for export.

The area also became a centre for the manufacture of railway locomotives, with such firms as Todd, Kitson and Laird, Fenton, Murray and Jackson, and E B Wilson and Co. When E B Wilson closed in the 1850s much of the equipment and patterns were purchased by Manning, Wardle and Co, with the result that Manning's early locomotives looked like E B Wilson's products. In 1860 yet another locomotive manufacturer appeared on the scene with the opening of Hudswell, Clarke and Co. The latter would be the last of the Leeds locomotive builders to remain in business, surviving into the 1990s. By the 1850s, Kitson's Airedale foundry was turning out traction, stationary and ploughing engines for John Fowler, though Fowler eventually opened his own works.

Later still, Samuel Fox developed pressed-steel railway bogies and wagon underframes. Though Leeds had become a major engineering centre, iron-making was always on a small scale and even in 1871 there were only two blast furnaces in the borough. There were, however, a large number of foundries, such as the Leeds Forge Co and Kirkstall Forge Co, producing all manner of castings. Towards the end of the 19th century the production of wrought iron declined as steel gained in popularity. Most firms switched to using steel imported from Middlesbrough, Sheffield and Rotherham.

It has been estimated that by 1881 around 80 per cent of England's population was living in towns, compared with only 25 per cent in 1800. Though Leeds continued to play a major role in the woollen industry, competition was increasing and several large mills diversified into dyeing and finishing.

By the 1891 census the textile industry was employing 22,313 workers, a slight reduction over 1881, but clothing manufacture had nearly doubled to 30,172 employees, and an additional 23,000 manufacturing and 32,000 transport, professional and service-sector jobs had been created in Leeds. Still Leeds continued to grow. By the 1911 census the population stood at 445,791. It was all far removed from the tiny hamlet of 1085.

Further Reading

To discover the histories of other local UK places, visit our Frith History homepage.

Leeds History in Photos

More Leeds PhotosMore Leeds history

What you are reading here about Leeds are excerpts from our book Leeds Photographic Memories by Clive Hardy, just one of our Photographic Memories books.